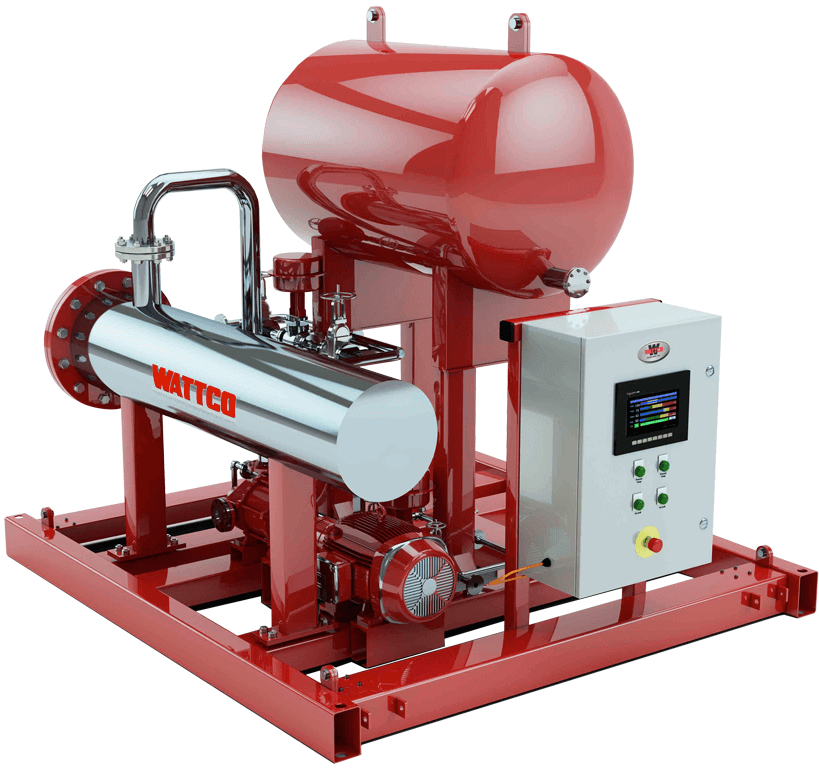

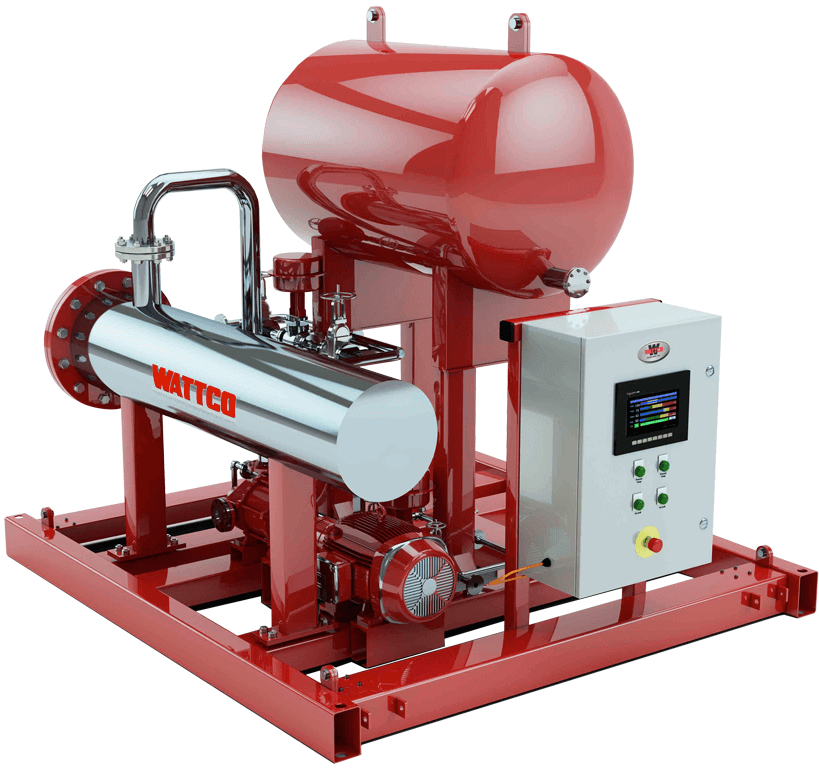

Themic Fluid Heating System Skid

Thermic Fluid Heating System Skid Manufacture

Thematic Fluid Heating System Skid, asp industrial solution, The motion upgrade of the asp industrial solution is an urgent consideration in acquiring improvements in energy productivity in exchanger applications.

Current energy demands and thus the desire to expand the efficiency of frames have prompted the opportunity to improve heat moving surfaces. The use of improved heat movement tubes is an effective technique within the advancement of elite warm frames.

Less mess

Quick refund

More modest establishment impression

Accessible over many composite frames

Upgrade on one or each side of the cylinder

Accessible improved level sheets

More uniform properties than ordinary improved tubes

Useful for high volume production

Region expanded by up to 25%

We assemble and assemble boilers of different types such as steam boilers, hot air generators, thermal liquid radiators, dilemma generators, pellet burners, etc. Its latest innovation is intended for direct and productive activity.

Components:

programmed

Simple Pump Activity and Confirmation Framework

Various types of finishing liquids.

Current plan and quality material.

High limit More competent

Monetary flawless and keeping up

The hot air generator is made up of a necessary chrome steel shell-type combustion office housed within the shell. The air is infused into the main path by a suitable boundary fan, it retains heat from the vent gas inlet, and so both hot pipe gas and cold flight into the alternate path within the section that, in the long run, changes in temperature to 90 degrees. into the cold air and carries the hot air from the opening of the hot air supply.Themic Fluid Heating System Skid

Themic Fluid Heating System Skid Manufacture in Vadodara

The utility of the hot air generator is programmed by a temperature sensing device inserted in the hot air outlet that turns the burner on and off at the preset temperature. The structure can be a package type unit, fixed on the edge of the normal base.

asp industrial solution manufactures hot liquid radiators for constant implantation in creation plants of any mechanical area. Our heating paddle structures are designed to meet customer needs when a portable and adaptable arrangement is required.

Lately, Themic Fluid Heating System Skid,due to the growing interest in more flexible units, the size of the skates created by the asp industrial solution has been expanded, leading to a replacement configuration line.

In this way, we produce versatile radiators formed as a preservative pallet, for use in both heating and cooling measures.

We carry out “redone” executions, planning each landslide according to the prerequisites of the top client, be it hot oil stove, or only by distribution units or auxiliary meetings. Most of the focuses of these pallets are the black cover area and petrochemicals; the automotive industry or the wood area, for heating presses, etc.Themic Fluid Heating System Skid

The item is heated through ignition gases, fire radiation or electrical heating components, without any delegated liquid.

It is the preeminent basic and justifiable framework, which we use every day within the kitchen gathering when the oven burner heats the container that contains the food. It can also be up to the task of heating something on a stove or microwave.

During the strategy, the burning gases are removed to the surface through the pipe.

Themic Fluid Heating System Skid Manufacture in Gujarat

As soon as the product reaches the predefined temperature, the burner is deactivated.

A medium of the road is used, which runs in a controlled manner between the radiator and thus the heat buyer, referred to as heat moving liquid.

The expression “move liquid” is conclusive to understand the frame.

A heat movement circuit is one during which the glow carrier flows from the heater to the heat buyer and then at that point returns back to the radiator or heater and during which, between the boundary dividers of the structure, heat is neither added or removed. of, except for the misfortunes in the weather.

An illustration of an ordinary heat movement frame, considering the ordinary things, is that the homegrown heating frame was introduced in many homes.

Due to the many benefits it has over direct heating, indirect heating through heat moving liquid is the main framework used in modern areas.

The main benefits are:

Industrial asp solutions are often introduced in the most helpful place, not too close to the edge of any of the buyers, avoiding opportunities and expanding security conditions.

The need of a fuel supply to each place of use and an ignition gas pipe for each purchasing appliance, increases the resolution of the immediate heating plant, so it is important to excuse the helpful areas due to the assembly flow.

Themic Fluid Heating System Skid Manufacture In India

Being a concentrated frame, the measurement of defenseless components against maintenance and breakdowns is much more modest than in the case of direct heating, with a burner for each customer machine.

Heater exposure and energy productivity is much higher in rotary heating, as the hardware is implicit in light of this. Direct heating should be tailored to the qualities of the buyer’s appliance to recognize infrequent burns that are ideal.

asp industrial solution is Themic Fluid Heating System Skid kept away from overheating of the product to be heated and, in this way, there is a high consistency of temperatures, it is controlled with precision and thus the ultimate nature of the strategy is ideal. Each customer appliance can have its own working temperature, controlled as if it had its own unique heating.

Heating and cooling measures, whenever necessary, are regulated with a comparable heat carrier and identical frame.

It allows the development of sub-organizations of situations, hot air or steam, by means of heat exchangers.

The thickness of the protection inside the client is more conservative since the sole where high temperatures are reached is inside the heater. This is particularly important when there are a large number of buyers.

With this examination of heating strategies, we have characterized a heat moving oil circuit, as long as, as in the case of indirect heating, it is most of the parts that we have recently discussed and shown in the figure. 3: evaporator, burner, vent, pipes, buyer machine, and the glow move liquid.Themic Fluid Heating System Skid

To complete the glow move liquid circuit, we have two fundamental components: the distribution siphon and, in this line, the development tank.

During a homegrown problem heating plant, a siphon is also needed to circulate the liquid from the kettle to the buyer’s appliance and ensure its new visit to the heater. Also, a tank is needed to absorb the development of the carrier liquid due to the increased temperature.

Due to the homegrown heating frame, both the siphon and the extension tank, due to their small size, are generally built into the kettle, which could lead to the misconception that they do not exist.

The extension tank is associated with the frame by means of a line, referred to as a payment pipe, which allows us to send the expanded volume delivered by heating the entire circuit to the tank and, within the cooling stage or end of the day, to replace lost time with the lower level created by a rise within the thickness of the liquid after cooling.

The last thing that will be added are the small essential more elements, for example, fittings that allow us to disconnect any device or buyer from the frame, both for maintenance and well-being; a line to be used to fill and exhaust the structure; and a channel to protect the distribution siphon from possible degradations that exist inside the pipe. the fundamental circuit, but, is now determined.

About US

ASP Industrial Solution is an Engineering Consultancy based at Vadodara, Gujarat in India catering Engineering Services to various Industries like Chemical, Allied Chemical, Agro Chemical, Petrochemicals, Oil & gas, Bulk Drugs, Pharmaceutical and Speciality Chemicals etc.

Registered/Work address

SF/12, Petal Trillium Before Navrachna University @ 24 MTR, High Tension Rd, Bhayli, Vadodara, Gujarat 391410, India.

E-mail:

info@aspindustrialsolution.com,

aspind.solution@gmail.com